SURFACE PREPARATION

Conduct a splash test on bare wood to confirm water

absorption before applying this product. Note: Chlorine

bleach cleaners alone are not recommended. These

products degrade the wood structure, interfering with

penetration and adhesion of protective coatings.

To conduct a Splash Test, sprinkle several handfuls of water

on a few distinct areas of the bare wood surface. If the

water absorbs rapidly, the surface is ready to be coated. If

the water beads, puddles or is not absorbed, an internal or

external barrier exists, which must be eliminated before

application of the preservative finish.

Prepare the surface withWolman® DeckBrite™(Powder Concentrate),

Deck & Fence Brightener (Liquid Concentrate) or DeckStrip®

products and repeat the splash test to confirm water absorption

before applying this product.

UNCOATED, NEW WOOD: It is important to open wood

pores and remove any surface barrier which would

prevent the proper penetration or adhesion of a new

coating. If the wood is pressure-treated lumber, excess

surface wax or excessive internal moisture content may be

present. If new wood is Cedar or Redwood is used, “mill glaze”

on the surface is a common condition. Use either Wolman DeckBrite

powder concentrate or Deck & Fence Brightener liquid concentrate

according to label directions, then conduct a Splash Test. If

absorption is not improved, allow the wood to dry a minimum of

30 days in temperate weather (70° F and 50% RH), longer in cooler or more

humid conditions. Test for absorption again before applying this product.

UNCOATED, WEATHERED WOOD: Before coating, weathered wood must

be thoroughly cleaned to remove the grayed, UV damaged wood surface,

ground-in dirt,mildew and algae stains, and other surface contaminants.

Use either Wolman DeckBrite powder concentrate or Deck & Fence

Brightener liquid concentrate according to label directions to prepare the surface.

PREVIOUSLY COATED, WEATHERED WOOD:

Previous coatings should be removed before application of this

product. If pigmented oil or latex coating exists, use

Wolman DeckStrip Stain & Finish Remover according to

the label directions to prepare the surface. Acrylic coatings

may require a paint stripper. If coated with a clear sealer

or the remaining finish contains little to no pigment, use

Wolman DeckBrite powder concentrate or Deck & Fence

Brightener liquid concentrate, followed by pressure

washing to restore the surface and remove and residual

coating or water repellent.

Before applying this oil-based product, wait at least 24

hours after cleaning, stripping or power-washing to

allow the water-soaked wood to dry out thoroughly.

Oil-based finishes will not properly penetrate wood

that is water soaked.

APPLICATION

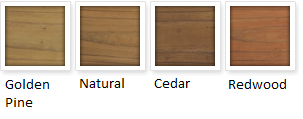

BEFORE YOU START: Prior to project start date,

perform a trial brush-out in several inconspicuous areas to ensure

the desired color is achieved. Color appearance will vary

depending on wood species, age and surface porosity.

Replace rotted, extremely weathered or warped boards.

This product will not repair existing wood damage such as

cracking, checking, splintering or splitting. Make sure entire

wood surface is dry and free of dust, dirt and debris.

Cover all surrounding areas not intended to be coated.

Intermix or box multiple gallons of the same product color

in a separate container to ensure a uniform color. Do not

tint, dilute or mix this product with any other product.

Mix product thoroughly before use and stir occasionally during

application.

Apply when outside temperatures are between 50-90°F(10-38°C)

and when no precipitation is expected for 24 hours.

Do not apply to wood that is hot to touch or in direct

sunlight to prevent premature evaporation of solvent.

Apply with a natural or synthetic bristle brush, paint pad,

pump sprayer, or airless sprayer. When spraying, work on

a 30-40 square foot area at a time, making sure to back

-brush along the grain any drips, runs, uneven coverage or

surface puddles. Do not over-saturate surface with product

or allow to puddle to prevent shiners, tackiness, excessive

drying time or uneven appearance when dry.

Horizontal Surfaces:

Apply one liberal, uniform coat on decks and other horizontal surfaces.

Thoroughly coat all exposed surfaces until the wood will not absorb additional

product and avoid puddling. A second coat is recommended only if the wood

is highly porous. To test for this condition, check the penetration rate of the

first 30 square foot area coated. If the coating is dry to the touch

in 15 minutes or less, then another light coat may be applied no later than one

hour after the first coat. Only half the amount is necessary for the second coat.

Vertical Surfaces:

Apply two wet-on-wet coats on shake,

shingle or lap siding, roofing, fences and other vertical

surfaces. Do not allow product to dry fully between coats.

Apply a second coat within 6 hours of the first coat.

This product must penetrate the surface to work properly.

Do not apply to a sealed wood surface. Do not use as a

primer coat.

DRY TIME

Because temperatures and humidity fluctuate,

allow a minimum 24-48hours before using deck,

porch, or outdoor furniture, and 72 hours before returning furniture

to deck/porch surface. Avoid dragging furniture across surface.

On newly treated surfaces, allow 7 days for coating to cure before washing.

CAUTION: BARE WOOD OR COATED SURFACES

CAN BECOME SLIPPERY WHEN WET.

Use caution when walking on wet surfaces.

CLEAN UP

Wipe up wet coating splatters and spills immediately with

mineral spirits. Dried spills can be removed with lacquer

thinner or mineral spirits. Clean up tools and equipment

immediately after use with mineral spirits.